Plus, it guarantees that projects are overseen, maintained, and successfully completed.The term "Six Sigma" refers to a statistical measure of how far a process deviates from perfection.

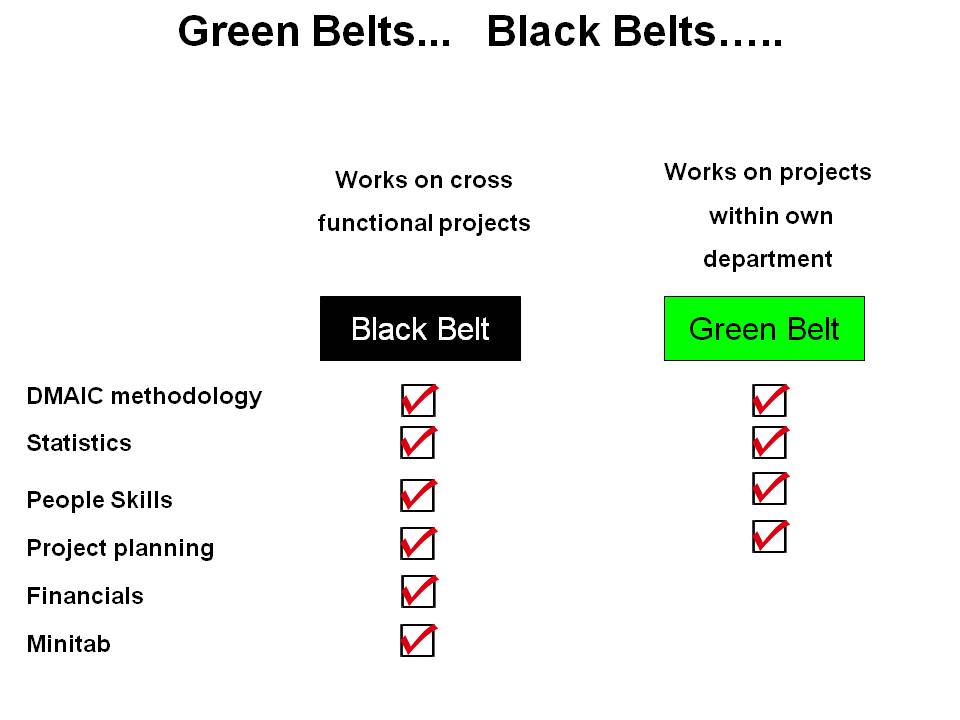

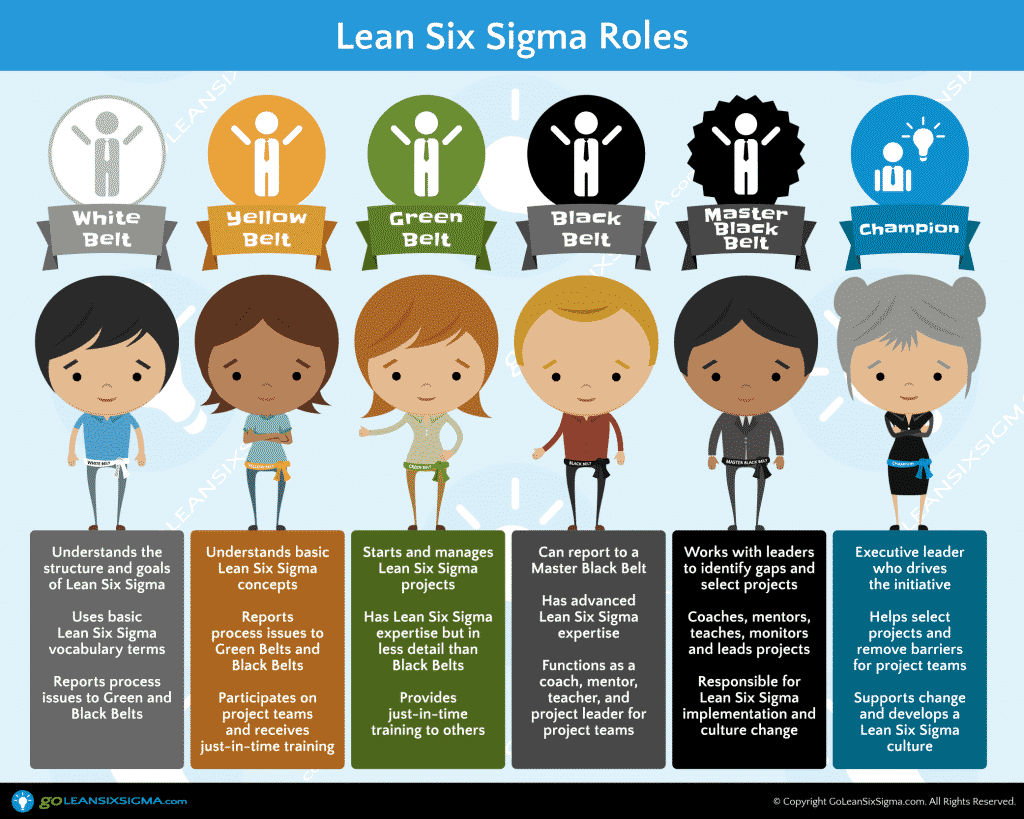

Varying certifications among employees ensures that you have enough support at each level and all participants are sufficiently coached and mentored. It doesn't make sense to have everyone trained as a Green Belt. If you're an organization looking to introduce Lean Six Sigma into your workplace, we recommend a "just-enough" approach to training until your project efforts yield returns. But how far you go in your training will depend on your ambition, role and responsibilities.

Point blank, everyone benefits from understanding the basics. No matter the belt level you choose for your role, your career will benefit. Additionally, they help coach Black Belts and Green Belts through their projects and their own leadership challenges. Master Black Belts will often lead entire process improvement initiatives.

#Six sigma belts meaning how to

Master Black Belt programs build on the foundation of the previous belt levels and help you understand how to lead complex enterprise‐wide projects, develop the technical and process excellence skills of teams, and support organizational transformation at the executive level.Ī rare belt‐level achievement, Master Black Belts are seasoned Black Belts that will have extensive advanced training in design, stats, and modeling. The Master Black Belt level will help you become an expert in operational excellence. Black Beltīlack Belt training takes significantly more time and effort than yellow or green belt training, but is perfect for those seeking roles of leadership in project management or process improvement.

Since the training involves more in‐depth analysis, Green Belts will also know a considerable amount of statistics. Green Belt programs also provide some leadership training for small project team management with the assistance of other Green Belts or Yellow Belts. When Green Belts are fully trained, they are equipped to lead their own DMAIC project. Green belt professionals should expect around 80 hours of comprehensive training. This includes things like communication, hypothesis testing, Statistical Process Control (SPC) Charts, and much more. White BeltĪs a level‐up from Yellow Belt, Green Belt training goes a bit more in‐depth with Lean Six Sigma concepts.Ī popular option for those that want to become project leaders, green belt training covers everything that you would learn as a yellow belt, with added material. Here is a basic guide on the MoreSteam Six Sigma belt approach, and the different skill sets that each one brings to the table. Lean Six Sigma is just an approach to problem solving and there are lots of ways to get started. If you're not sure what to believe or what your options are, keep reading. When it comes to process improvement, everyone has an opinion about the best way to get started. Once you understand how DMAIC works, you'll never look at problems the same way again. This roadmap is taught and followed by MoreSteam, large global organizations, and many universities and institutes of higher education. This is an acronym for Define, Measure, Analyze, Improve, Control. The more complex the problem, the more sophisticated the tools necessary to solve it. So what is Six Sigma training? At its core, it's disciplined problem solving. Every level offers valuable insight, and deciding on which level to train employees should depend on the complexity of the problem that they need to solve. Each belt level, regardless of color, allows you to bring more value to your workplace.įrom a business perspective, in order to create a culture of organizational excellence, it's important to align the training with the specific roles that are needed to complete various projects.

0 kommentar(er)

0 kommentar(er)